Sustainability; It is defined as meeting the needs of today’s generation without compromising the needs of future generations. Sustainability as Eylul Textile Washing; It is the focus of our strategy and the lifeblood of our efforts to ensure a cleaner and healthier future for the world.

Today, consumers have begun to question how much harm the clothes cause to the environment and people during the production process. The importance of environmentally friendly denim washing processes has increased with the use of environmentally friendly chemicals, less water, less chemicals and less energy consumption, and the control of the use of natural resources.

We, as Eylül Textile Washing, are part of environmentally friendly production by using sustainable denim washing methods. The savings achieved in sustainable denim washing processes compared to traditional washing processes are generalized as follows:

- Water: 60% water saving

- Chemical: 30% chemical savings

- Energy: 40% energy saving

Note: These data are based on a general sustainable denim washing process. These data may differ according to the changing washing process.

- When compared to traditional denim washing method;

- Need for qualified staff,

- High cost new generation machinery investments,

Organic, environmentally friendly chemical costs further increases operating costs.

The savings mentioned in sustainable denim washing processes are the savings achieved in terms of the use of natural resources such as water and energy. Since there are expenses such as the need for qualified personnel, machinery investments and organic chemical costs mentioned above, there is no savings in product cost. The traditional denim washing process steps and sustainable denim washing process steps are tabulated below.

|

TRADITIONAL DENIM WASHING PROCESS STEPS (FOR DARK FLOORS) |

SUSTAINABLE DENIM WASHING PROCESS STEPS (FOR DARK FLOORS) | |

| 1 | Sanding-Mustache | Double Stage Laser Sander- Whiskers-PP Spray image |

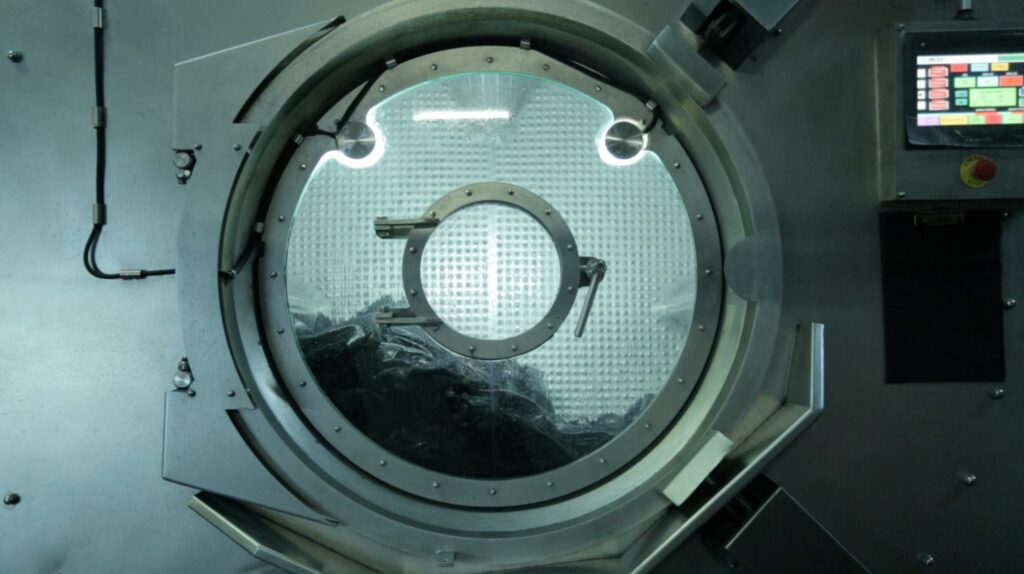

| 2 | Pre-wash | Enzyme washing (in eco-effect machine) |

| 3 | Rinse | Rinse |

| 4 | Stone / Perlite / Stone enzyme | Squeezing |

| 5 | Rinse | Flow Bleaching |

| 6 | Rinse | Rinse |

| 7 | Squeezing | Bleaching |

| 8 | Drying | Bleaching rinsing |

| 9 | PP Sprey | Neutral feather enzyme |

| 10 | Neutralization | Rinse |

| 11 | Rinse | Softening |

| 12 | Bleaching | Ozone |

| 13 | Rinse | |

| 14 | Acidic feather enzyme | |

| 15 | Rinse | |

| 16 | Softening |

| TRADITIONAL DENIM WASHING PROCESS STEPS (FOR MEDIUM AND OPEN FLOORS) | SUSTAINABLE DENIM WASHING PROCESS STEPS (FOR MEDIUM AND OPEN FLOORS) | |

| 1 | Sanding-Mustache | Double Stage Laser Sander- Whiskers-PP Spray image |

| 2 | Pre-wash | Enzyme washing (in eco-effect machine) |

| 3 | Rinse | Rinse |

| 4 | Stone / Perlite / Stone enzyme | Squeezing |

| 5 | Rinse | Flow Bleaching |

| 6 | Rinse | Squeezing |

| 7 | Bleaching (Hypo or PP) | Ozone Bleaching |

| 8 | Rinse | Ozone rinse |

| 9 | Rinse | Bleaching |

| 10 | Squeezing | Bleaching rinsing |

| 11 | Drying | Neutral feather enzyme |

| 12 | Spray | Rinse |

| 13 | Neutralization | Softening |

| 14 | Rinse | |

| 15 | Bleaching | |

| 16 | Rinse | |

| 17 | Acidic feather enzyme | |

| 18 | Rinse | |

| 19 | Softening |

WATER, CHEMICAL AND ENERGY USAGE AMOUNT

FOR 1 PRODUCT (0.5 KG);

| TRADITIONAL DENIM WASHING | SUSTAINABLE DENIM WASHING | SAVING PERCENTAGES | |

| WATER | 50 L | 20 L | %60 |

| CHEMICAL | 65 g | 45 g | %30 |

| ENERGY | 2,5 Kwh | 1,5 Kwh | %40 |

Note: These data are based on a general sustainable denim washing process. These data may differ according to the changing washing process.

Turkish

Turkish